Merry Christmas and Happy New 2023

It’s the most wonderful time of the year and our customers are the most wonderful part of our business! The team at EccoFab wishes you all a joyous Christmas and a prosperous New Year.

It’s the most wonderful time of the year and our customers are the most wonderful part of our business! The team at EccoFab wishes you all a joyous Christmas and a prosperous New Year.

As Sullair celebrates its 50th year providing compressed air solutions – Gerry Bauer shows how Sullair keeps its promise of Always Air. Always There.® Bauer, president of EccoFab in Rockford, IL, purchased his Sullair compressor in 1979 – and more than 35 years later it continues to run strong.

Our client, operating in an exceptionally demanding work environment, faced a recurring and challenging issue. Their OEM cutting edges, typically designed to last for extended periods, were lasting a mere 10 weeks in this rigorous setting. This rapid wear rate presented a double-edged problem. Firstly, it significantly escalated their maintenance…

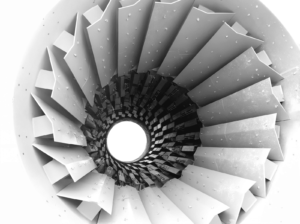

At EccoFab, our mission is to constantly innovate and revolutionize the aggregate industry by designing and manufacturing products that increase productivity, reduce costs, and maximize equipment longevity. A perfect example of our commitment to this mission is our new Heat Resistant Asphalt Drum Flighting. This groundbreaking product boasts a superior…

EccoFab’s Heat Resistant Asphalt Drum Flighting Makes “Asphalt Contractor’s Top 30 Products 2024 We are thrilled to announce that EccoFab’s Heat Resistant Asphalt Drum Flight has been named one of Asphalt Contractor’s Top 30 Products for 2024. This prestigious list recognizes the best new products and long-standing innovations in the…

We are excited to announce that our company will be showcasing our latest wear parts for the aggregate industry at the upcoming CONEXPO-CON/AGG trade show in Las Vegas, Nevada! We will be located at Central Hall – Booth #30958. We invite you to come see us and learn more about…

Hardox® 400 is an abrasion-resistant steel with a nominal hardness of 400 HBW. Hardox® 400 is an all-around wear-resistant steel. Thanks to its high toughness, good bendability and weldability, this steel can be used in structures with moderate wear. Due to its high abrasion resistance, Hardox steel is often used…