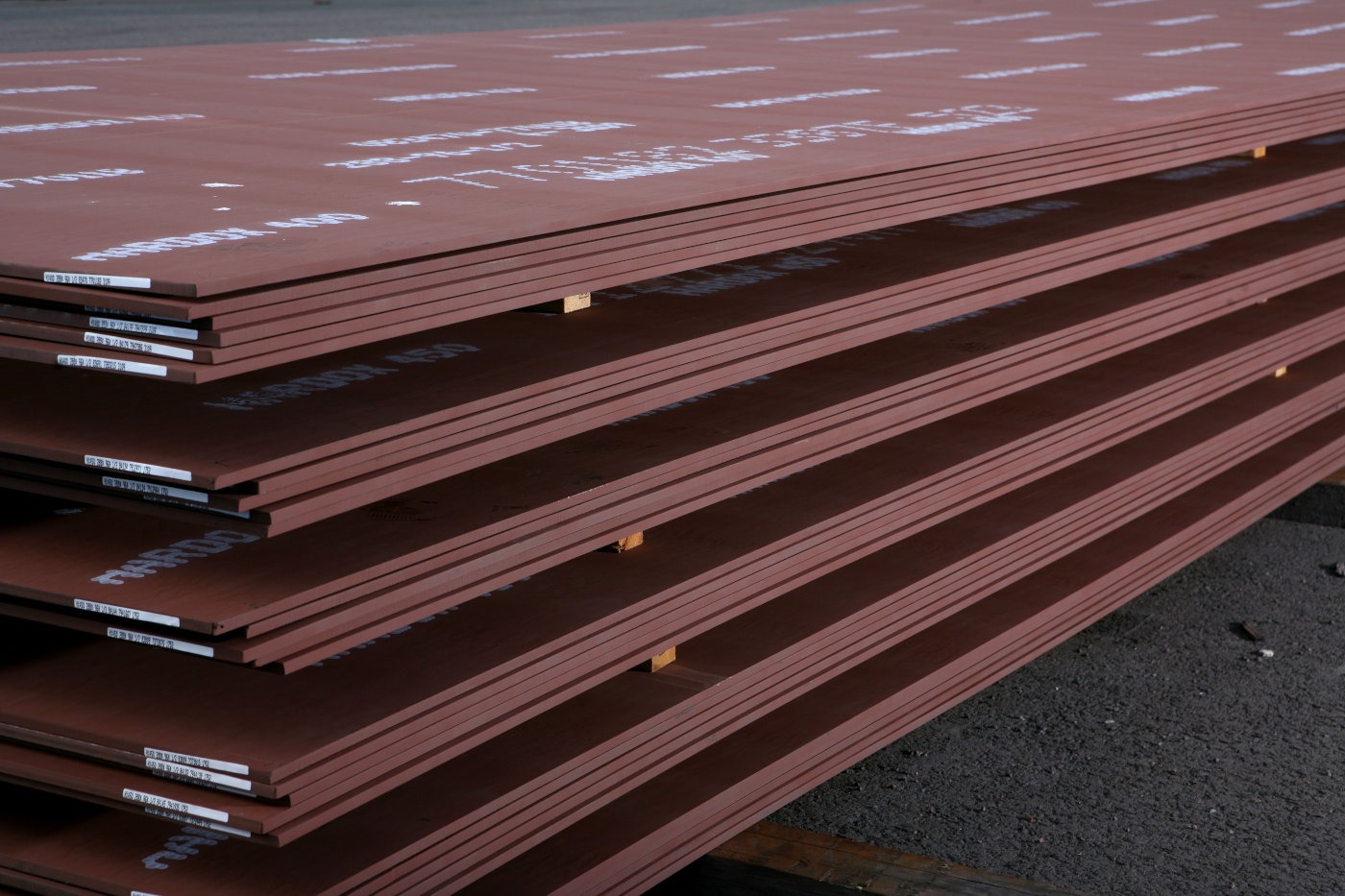

Hardox® 400: The all-around steel that resists wear and abrasion.

Hardox® 400 is an abrasion-resistant steel with a nominal hardness of 400 HBW. Hardox® 400 is an all-around wear-resistant steel. Thanks to its high toughness, good bendability and weldability, this steel can be used in structures with moderate wear.

Due to its high abrasion resistance, Hardox steel is often used for the manufacture of:

- dump and trailed truck bodies, which are used to transport rocks, agricultural products, construction waste and other materials with increased abrasiveness;

- garbage truck bodies, which are constantly exposed not only to mechanical but also to chemical stress;

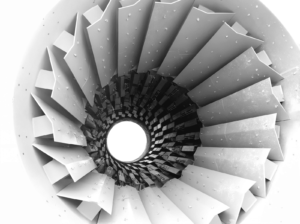

- excavator buckets, bulldozer shovels and tractor attachments subject to particularly severe wear;

- containers for various purposes, including for the transportation of aggressive substances;

- supporting structures that must be strong and lightweight at the same time.

SSAB began producing Hardox wear-resistant steel products in 1983. Since then, the company’s technologists have been constantly working to improve the product, thanks to which it surpasses its counterparts in terms of the combination of hardness and ductility. Manufacturing facilities are located in Sweden, Finland and the United States.

Hardox® 400 is available as plate in thicknesses of 4.0 – 130.0 mm, and as sheet in thicknesses of 2.0 – 8.0 mm. Hardox® 400 plate is available in widths up to 3350 mm and lengths up to 14630 mm. Hardox® 400 sheet is available in widths up to 1650 mm and lengths up to 16000 mm.

Mechanical Properties

| Grade | Thickness (mm) | Hardness (HBW)* | Typical Yield Strenght (MPa) |

| Hardox® 400 sheet | 2.0 – 8.0 | 370 – 430 | 1100 |

| Hardox® 400 plate | 4.0 – 130 | 370 – 430 | 1100 |

*Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface. At least one test specimen per heat and 40 tons. The nominal thickness of supplied plates will not deviate more than +/- 15 mm from the thickness of the test specimen used for hardness testing. For sheet the Brinell hardness test is according to EN ISO 6506-1 on each heat treatment individual/coil. Hardness is measured on a milled surface 0.3 – 2 mm below surface.

Tolerances

Thickness

Tolerances according to Hardox® Thickness Guarantees. Hardox® Guarantees meet the requirements of EN 10 029 Class A for plate and ½ EN 10 051 for sheet.

Length and Width

According to SSAB’s dimension program. For plate, the tolerances are according to SSAB´s mill edge standard or tolerances that conform to EN 10 029. Tolerances conform to EN 10 051 for sheet, tighter tolerances available on request.

Shape

Tolerances are according to EN 10 029 for plate and EN 10 051 for sheet.

Flatness

Tolerances are according to Hardox® Flatness Guarantees Class D for plate, which are more restrictive than EN 10 029. For sheet, the tolerances are according to Hardox® Flatness Guarantees Class A, that offer narrower tolerances compared to EN 10 051.

Surface Properties

According to EN 10 163-2, Class A Subclass 1.

Bending

Bendability for plate is according to Hardox® Bending Guarantee Class E. For sheet, the bendability is according to Hardox® Bending Guarantee Class A.